Feeding & Delivery Units

Modular Design for Finishing Ease

Rollem offers a range of products designed to meet the production needs of printing operations of all sizes. In this section, we highlight various types of Feeders and Delivery units.

Whether you’re seeking a standard configuration or require a semi-custom solution, our team is ready to discuss your specific requirements and help identify the best configurations and finishing methods to ensure the success of your project. Below, you’ll find information on Feeding and Delivery units, some of which come standard with certain Rollem models, while others are available as optional upgrades.

For more information, also visit our Automation & Integrations section to explore near-line, in-line, and custom configuration options.

Feeding Systems

Friction Feed

Rollem’s Champion 990 scoring, slitting and perforating model is designed with a friction feeding section. Once powered on, the concentric roller feeds shallow stacks of material into the machine. Ideal for lower to mid volume runs.

Deep Pile Airfeed

This higher capacity feeder is powered by air for feeding larger quantities of material typically produced on Jetstream and TR systems. The fully automated feeder accepts full pallets of material for fully automated, uninterrupted processing.

BSF Sheet Feeder

This unit is available for in-line feeding with a Rollem Jetstream system. The feeder improves production output by utilizing stacker carts to move media in and out of the feeding device.

Delivery Options

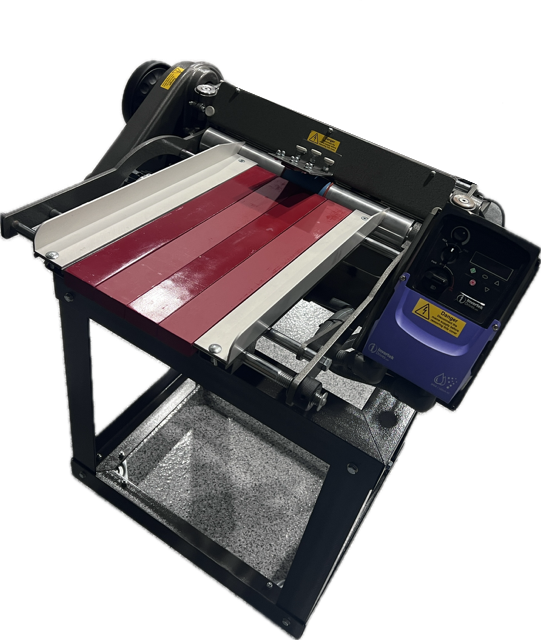

Shingle Belt Delivery

The slow-moving shingle delivery table improves output handling as products are fed and shingled for ease of offloading from the unit. Configurations can vary from a single land of product up to 6 -12 lanes depending on the size of the finished product. These units are offered in either 3’ or 5’ lengths with 24” or 32” widths.

StackMaster

Rollem’s StackMaster units offer the option for delivering individualized products such as business cards or postcards into a vertically receding stacking system capable of receding up to 24” deep. Product is delivered into a removable cassette for minimal downtime. Available in 24” and 30” widths.

Folder Gluer

These systems offer versatility and converting capability, in a smaller footprint. The unit may be customized with hot or cold glue, tip-on, window patch, and inspection options. It operates as either a stand-along system or in-line with Insignia Die-Cutters or Rollem Slitting, Scoring and Perforating systems. Available in either 2.5 meter or 3.5 meter lengths.

Auto-Collator

The Auto-Collator unit is used in conjunction with Rollem’s XY Slitting systems such as the Slipstream, Revolution and Jetstream. These systems handle multiple-up imaged sheets of playing cards, game cards, business cards and postcards. Once the rows of products are cut the Auto-Collator accepts cards onto a divided section which sweeps the sub-packs together and delivers complete sets of products — all at record speeds.

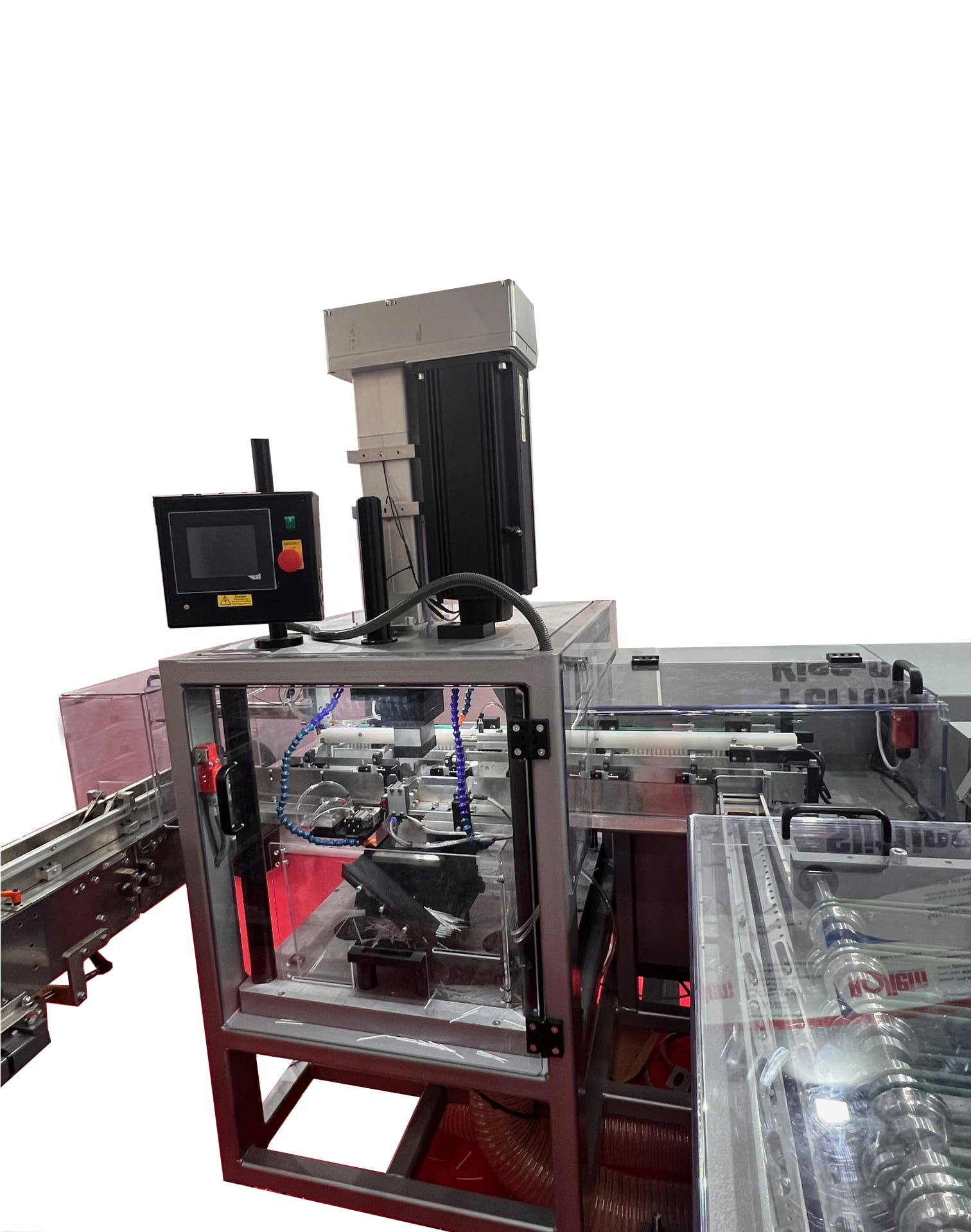

Over-Wrapping Systems

Also used with Rollem systems, the output product is feed automatically into the cello-wrap unit for in-line wrapping. Other types of wrapping materials are also available upon request.

Tray with Magnets

Rollem’s magnetic delivery trays are fitted with any arrangement of magnets which can be easily moved and adjusted to handle the output of products being finished on the Rollem.

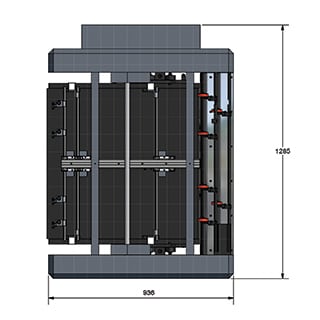

Card Cartridges

High Capacity Receding Bin Stacker