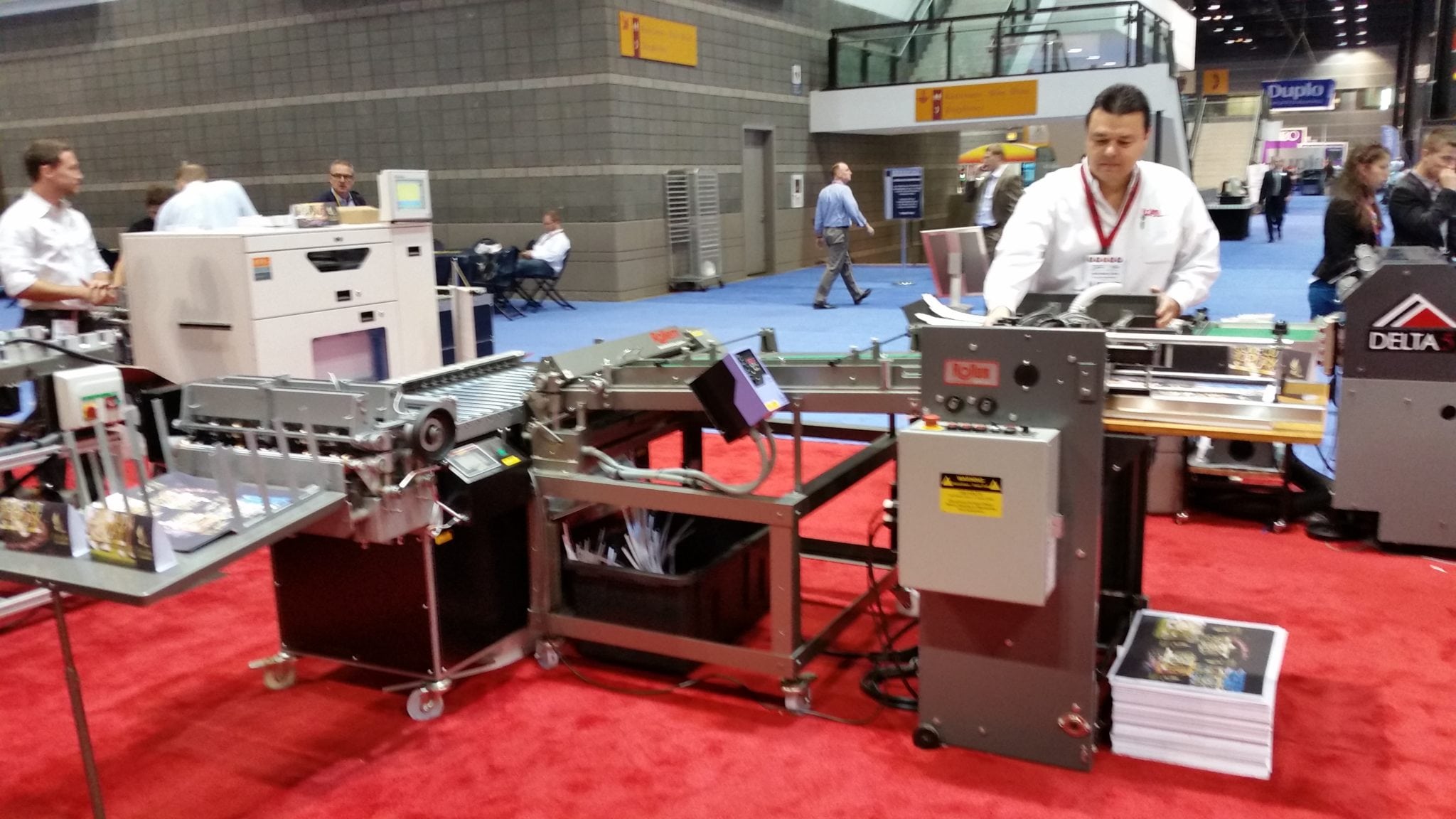

ETR Slitting, Scoring, Perforating & Semi-Slitting System

The ETR Perforating Machine is ideal for mid to high-level finishing. ETR stands for Economy TR.

Mid-level automation delivers perfectly accurate scoring, perforating, and slitting on all types of paper products. Ideal for mid to higher volume runs, The ETR streamlines your production with a deep pile feeder that accepts up to 30” of loaded stock at a time.

More profitable, completely versatile, absolutely accurate and very fast, the ETR will exceed all your expectations. Shafts are fitted with the desired slit, score or perf heads for a range of applications, including:

- direct mail

- brochures

- double gate folded literature and crossovers

- card products

- and more

Rollem’s ETR handles stocks ranging from 16 lb onion skin to 40 pt. Board flawlessly, as well as UV coated materials and cross-grained papers. Sheets are registered to the side guide and the air feed separates sheets for precise feeding sheet after sheet.

Features

- One operator can accurately place single-pass scores, perfs, slits, and bleed-slits

- Deep pile feeder accepts up to 30” of loaded stock at a time

- Available in single or double head/dual shaft configurations

- Vast array of specialty heads available, including micro-perforating blades

Benefits

- Increase accuracy, reduce wasted sheets, save on labor costs

- Streamline your production and complete orders in less time

- Double heads offer sharper creases with no cracking on difficult stocks

- Advance a higher quality finished product to your customers

Capabilities

- Scoring

- Perforating

- Slitting

- Strike-Slitting

- Right angle processing*

- Four-sided finishing*

*Requires Rollaway Right Angle Unit

Specifications

- Model Sizes: 24”, 30”

- Double head models: 24″, 29″

- Minimum Sheet Size: 6″ x 6″

- Maximum Sheet Size: 24” x 23” or 24″ x 29″

- Feeding System: Top Air Feed

- Stock: 20 lb to 20 pt. Board

- Speeds: Up to 15,000 sheets per hour

- Floor Size: 24″: 104″ x 38″ / 30″: 110″ x 44″

- Electrical Requirement: 220 Volt

- Gross Weight: 24″: 950 lb / 30″: 1,155 lb