Insignia 7

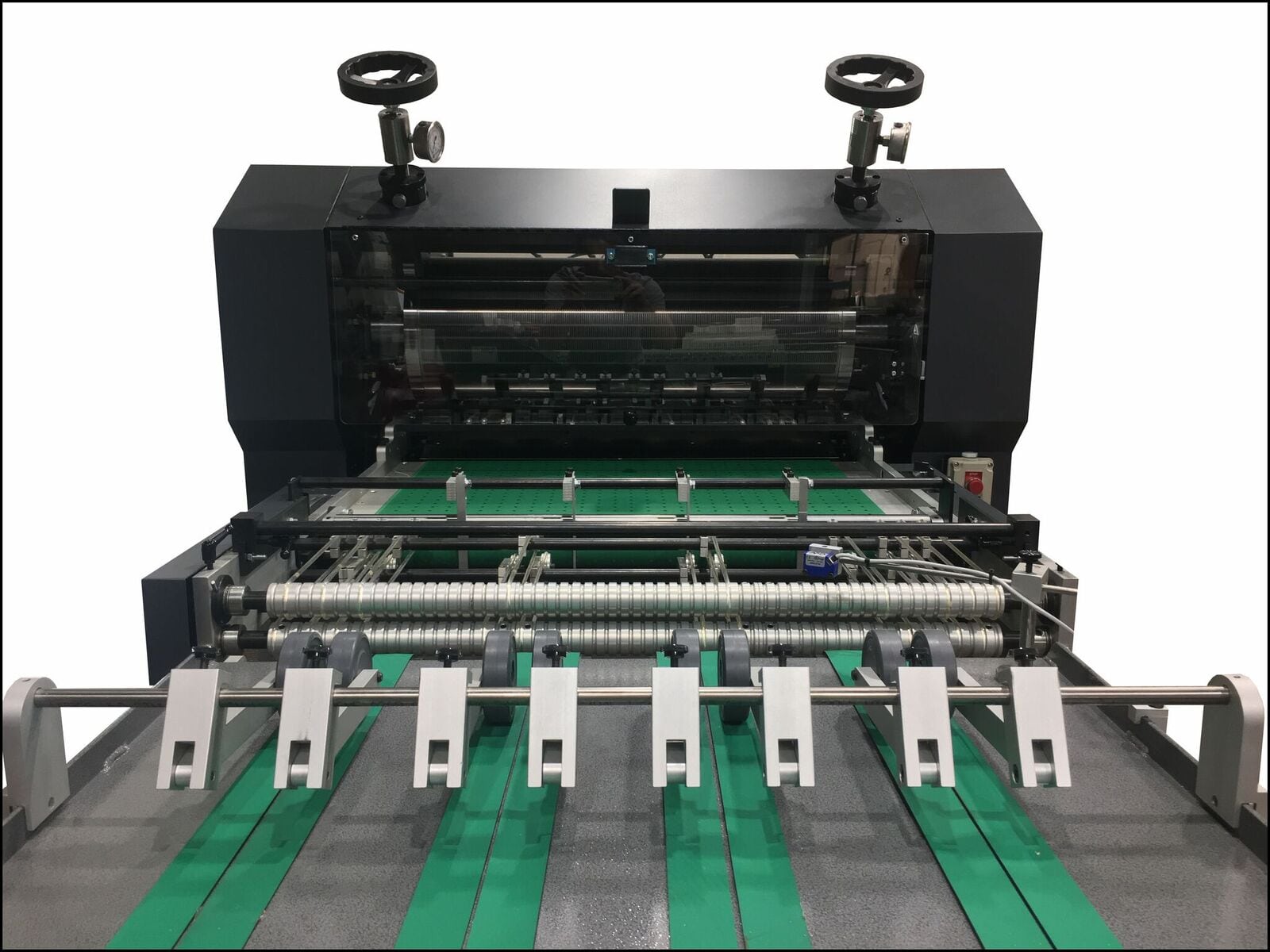

The Insignia 7 Die Cutter from Rollem is a breakthrough in die cutting and packaging technology. This new class of larger format die-cutting machine creates a distinct space in the print finishing market for sheetfed, short-long run label, packaging and mail applications.

IS7 models include a top and bottom magnetic cylinder for channel scoring boxes, packaging, greeting cards & presentation folders. Paired sets of dies allow for no make-ready, only switching sets of dies between jobs. IS7 is the ideal solution for die-cutting industrial name tags and component identification labels in a wide range of substrates, including foils, plastics and aluminum. This and other Insignia machines will cut plastic used for face shields.

Features

- Die cut, kiss cut and cut-score a virtually unlimited number of products

- Available with Bearered or Non-Bearered cylinders

- Available in offset or digital presses with a B2 format

- Ideal for HP Indigo 12000 and KM-1 UV Ink Jet Presses

Benefits

- Expand your service offerings and keep profitable operations in-house

- Prevents cutting displacement by transferring the point of stabilization to the cylinders

- Increasing output and productivity by fully utilizing the press sheet

Capabilities

- Kiss-cutting

- Embossing

- Perforating

- Scoring

- Creasing

- Hole punching

- Bearered Dual Mag configuration for presentation folders and packaging products designed with longer straight cut lines

- Non-Bearered Dual Mag configuration for running boxes on multiple types of substrates, kiss cutting pressure sensitive label stock, and scoring

PLUS Package

- Jobs can be saved into a recallable folder to auto-populate machine run speed, batch sequencing and other parameters.

- Set-up screen allows the operator to navigate during set-up. It controls over feed platform, pieces per sheet and skew input as well as code reading set-up.

- Easily adjust sheet set-up adjustments.

- Receive feedback via beeps to provide the operator with constant feedback on operating status.

Specifications

- Material Thickness:

- Minimum: 60lb Cover / 50gsm

- Maximum: 0.024” / 400gsm

- Sheet Size:

- 8×8” Minimum (20x20cm)

- 30×24” Maximum (76x61cm)

- Speed: Variable up to 5,000 sheets per hour

- Register:

- 8 Adjustable front head stops

- Side guide; pull left or right

- Gripper finger cam system

- Feed: Top suction air feed w/ 4 movable sucker heads. Front & side air separation. Feed capacity of ~40”

- Cylinder Options:

- Upper: magnetic, ceramic & steel

- Lower: Hard anvil, no jacket required

- Optional dual magnetic system

- Air Supply:

- Becker feed pump built in

- Compressed house air or air compressor required for stripping unit air knives.

- Electrical Requirements:

- 230v – 60Hz – 3-phase – 15 amp

- 110v 1-phase line

- *Other voltages available

- Footprint (Die Cutter Only):

- 79” long X 58” tall X 55” wide

- 200cm long X 147cm tall X 140cm wide

- Weight: 4,800 lbs / 2,200kgs

Select Impressions chooses the Insignia7H and Stackmaster for streamlined production of specialty folding cartons and business cards.

Based in Salem, OR, Select Impressions tagline is “Complete Visual Solutions”, with services including, offset and digital printing, mail, and specialty work.

Recognizing the need for updated bindery solutions, Mark DeWilde heard of Rollem’s Insignia sheet-fed rotary die-cutter and reached out to their Southern California facility. “Doug Sherwood, Sales Manager, listened to our needs and presented us with a private demonstration on the Insignia7H.”

Rollem’s Anaheim facility is the testing center for sample processing so we sent a supply of our 6-up carton sheets to be die-cut. “I was very impressed with the cut quality on the carton samples including the automatic waste stripping function of the IS7H”, states Mark DeWilde, Owner of Select Impressions.

“Having previously relied solely on a Heidelberg Windmill Die-Cutter and flatbed cylinder presses, the Insignia sheet-fed rotary Die-Cutter demonstrated to be much more time efficient and ideal for our high volume of assorted applications including a typical job of 6-up cartons, printed on a 19×25” sheet with runs of between 50K and 75K. The die-cut samples ran great, and we added the ‘Stack Master’ delivery section which is ideal for efficient handling of our volume of business cards (see photo)” continued DeWilde. The Insignia design is flexible and offers a shingle conveyor delivery option for presentation folders and folding carton work.

Anstadt Communications chooses the Rollem Insignia7 Die Cutter

Anstadt, 5th generation marketing experts, specializes in high-impact print enhancement and die cutting, everyday packaging, direct mail, signage, marketing collateral, and more.

Our Insignia 7 die-cutter is the latest finishing system to convert output from our HP Indigo presses with Scodix print enhancement. The IS7 continues to become a key part of our capabilities and success.

“The support from Rollem has been excellent. The B2 sheet capacity, its operation and solid operating speeds further enhance acceleration of information to market. Exactly what we needed in a converting system.”

MATT DORAN, PRESIDENT & CEO