Slipstream MKIII Card Slitter Collator with Auto Punch

Transform your trading, gaming and playing card production with the Slipstream MKIII by Rollem. By eliminating separate guillotine, collating, perforating, and creasing operations, the Slipstream MKIII removes the need for hand or machine collating, labor costs, factory space, and higher capital equipment costs.

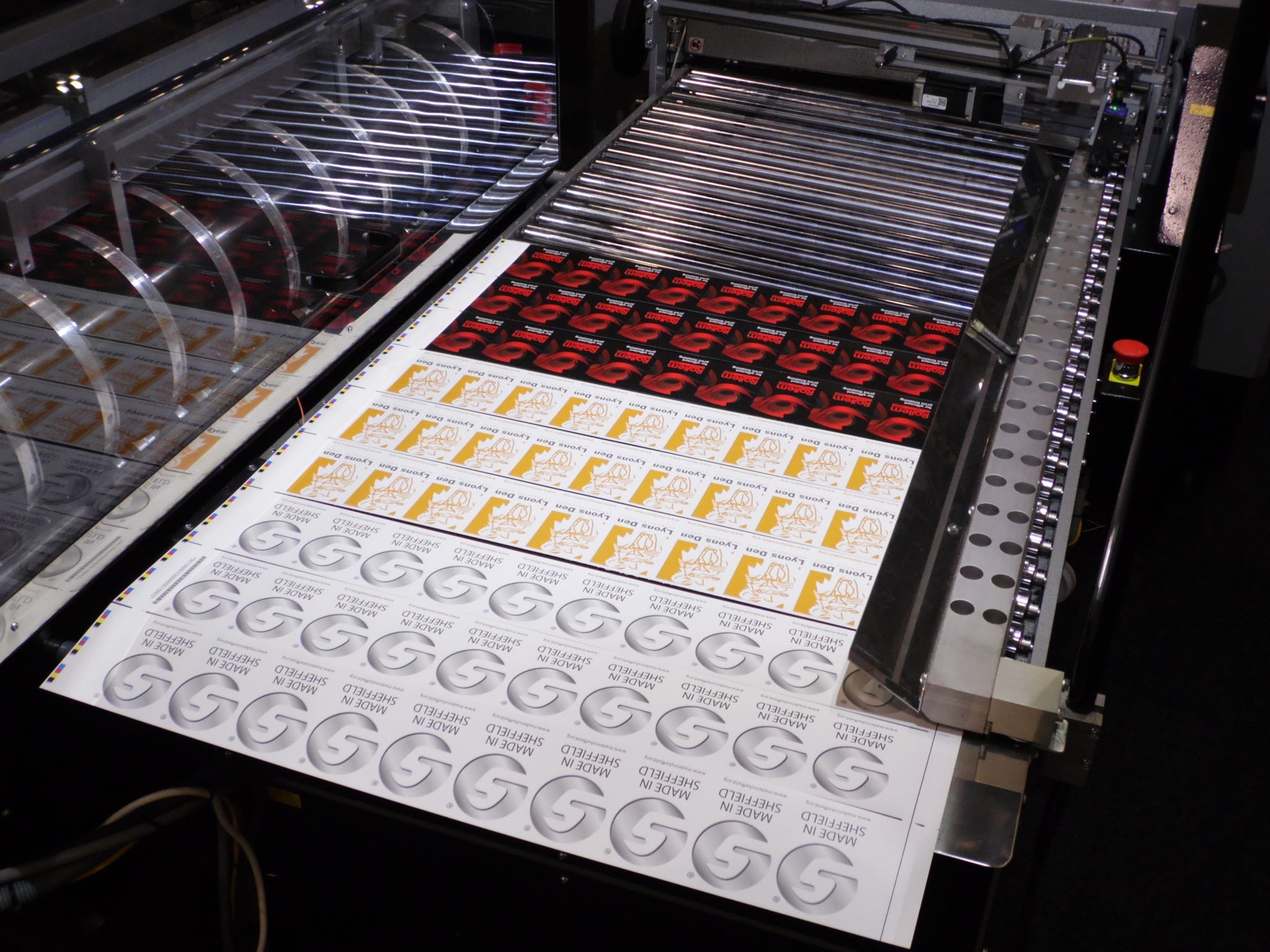

The diagram below shows how multiple-up image sheets are processed into single packs. The Slipstream systems precision card slitters produce decks used by the world’s top playing card manufacturers. The Slipstream’s products are so perfect that you can pull a piece from a deck processed six months ago and it will be a perfect mate to a deck processed yesterday.

Rollem Auto Punch

Fully automate your card pack production with the Rollem Auto Punch in-line attachment.

The Auto Punch accepts cut/collated card deck from the Slipstream and transfers them into the punching unit, where they are punched/die-cut with extreme accuracy. The Slipstream and Auto Punch can also run in-line with shrink wrapping and boxing systems.

With production speeds of up to 70 decks per minute, Slipstream Systems and Auto Punch are the most efficient, profitable method for card pack production.

Features

- One operator can cut, score, perforate, and collate up to 500,000 pieces per hour

- Trims all four edges of a sheet and the multiple printed images

Benefits

- Reduce logistics and manpower needs, as well as labor and higher capital equipment costs

- Fewer steps to complete each order

Capabilities

- Slitting/Cutting

- Collating

- Perforating

- Creasing

- Cuts the sheet into separate rectangular portions as small as 1 7/8” x 2 1/2”

- Perforates and/or creases each portion

- Collects and delivers cards into a fully collated stack or individual pack, with accuracy within 1/1000th of an inch

- Corner punch/die cut corners

- Transfers the packs to shrink wrap, banding or over-wrapping systems

Specifications

- Sheet Sizes: Up to 28″ x 40″

- Card Sizes: 1 7/8″ x 2 1/2″ Upwards

- Stock: 50 lb. Offset to 24 pt. Board

- Speeds: 500,000 Pieces Per Hour

- Trim Options: Common Boarder 2 or 4 Side Bleed Trimming

Applications

- Trading Cards

- Playing Cards

- Game Cards

- Coupons

- Business Reply Cards

- Postcards

- Greeting Cards

- Event Tickets

- Lottery Tickets, Scratchers

- Time Cards

- Currency

- Bingo Cards