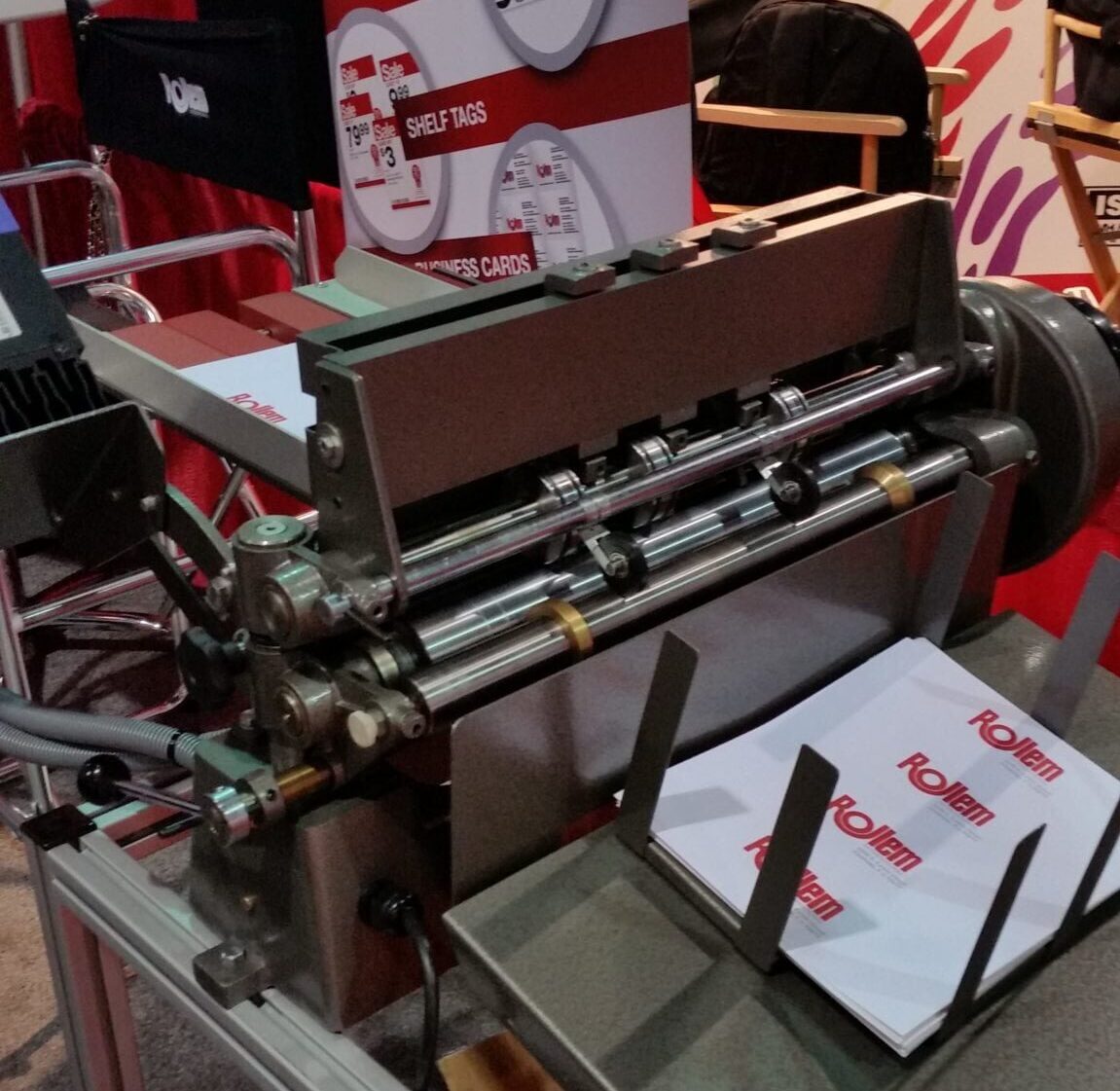

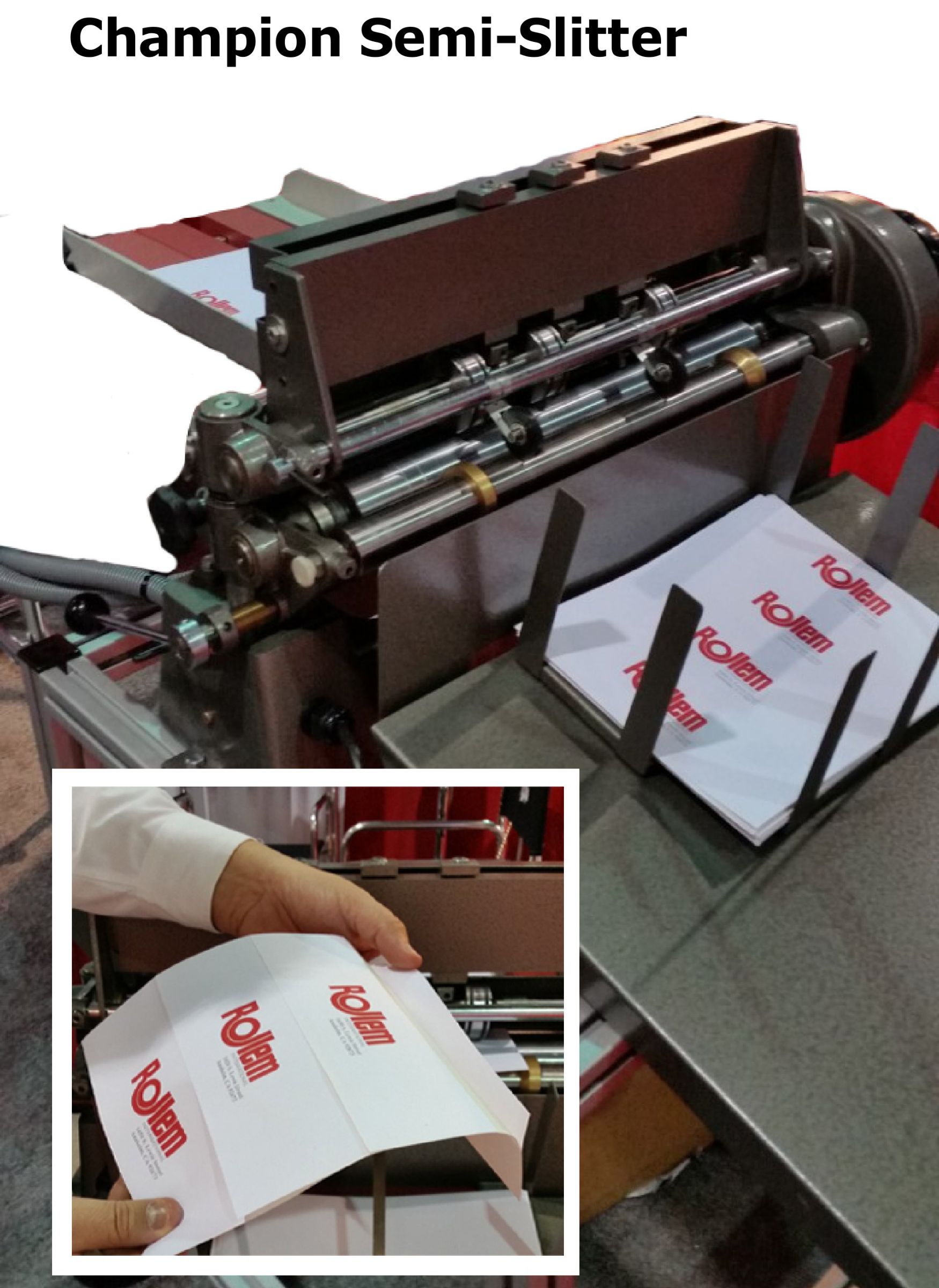

SS Semi-Slitter

Back and Face Slitting of PSA Liners

Back slitting or kiss cutting machines create a ‘crack and peel’ product for easy liner removal, leaving the label or pressure sensitive sticker ready to adhere to the desired surface.

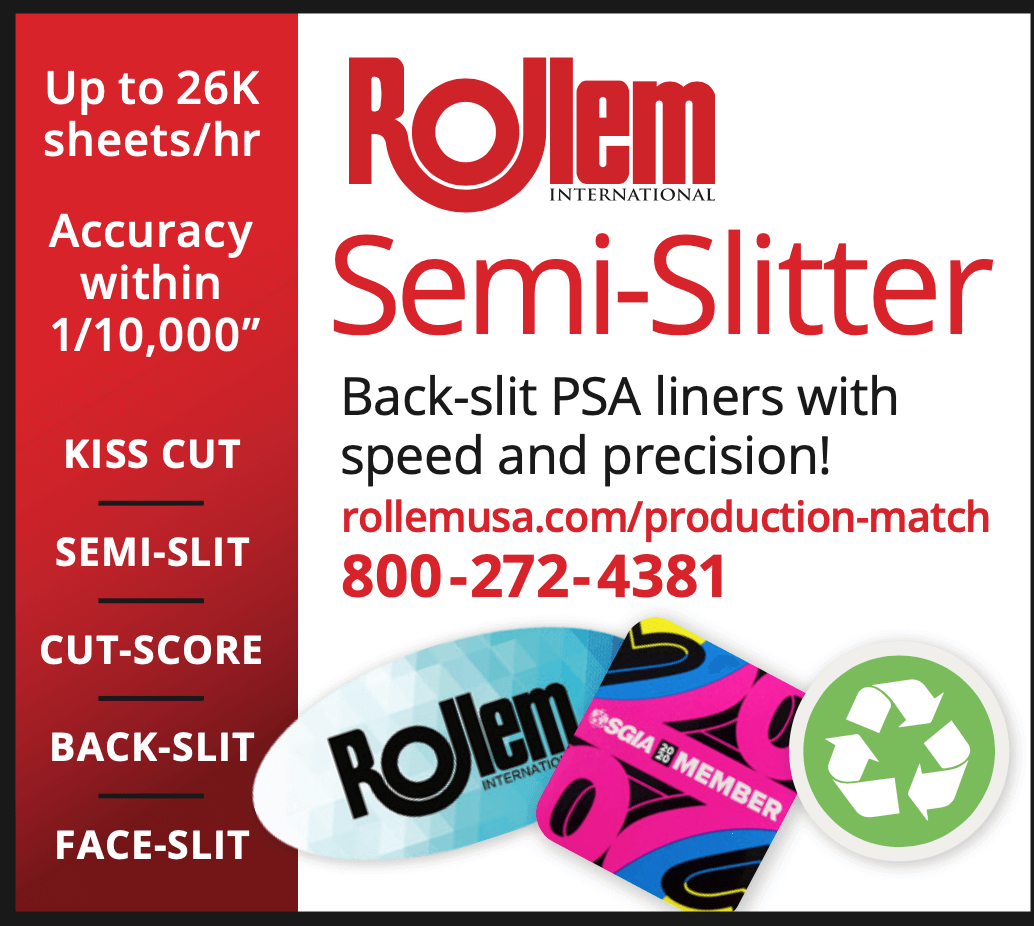

Rollem’s advanced SS Semi-Slitting/Kiss-cutting slitters allow you to back or face-slit stocks with precisely controlled cuts and easy depth adjustments on all types of pressure sensitive adhesives (PSA). With our superior stability and control, you can slit any material from fine paper stocks to heavy gauge plastics, with the same accuracy — sheet after sheet.

The SS is the top choice of sign and label companies to kiss-cut labels and stickers. We offer five model sizes to successfully back slit PSA (Pressure Sensitive Adhesives) in a variety of wide format outputs. Rollem has the widest range of kiss cutters on the market with five sizes of kiss cutting machine all the way up to 42” wide.

The Double Head model is configured with a two-shaft design allowing for one shaft of semi-slitting and the second shaft for scoring, perforating or slitting heads. The double head models offer these added functions if needed.

Features

- Margin of accuracy within .0001”; speeds up to 26,000 sheets per hour

- 2.5” hardened concentric roller for stabilization and support

Benefits

- Cost savings and faster order completions; higher profits on partial slitting PSA jobs

- Eliminates high and low cutting points to ensure precision and consistency

Capabilities

- Back slitting/kiss cutting

- Face slitting

- Models ranging from 18″ – 42″ wide

Single Head SS Specifications

- Model Sizes: 18”, 24”, 30”, 36” & 42”

- Sheet Size Minimum: 4” x 4”

- Stocks: 1 mil. up to 40 pt.

- Electrical Requirement: 220 volts, single phase

Double Head SS Specifications

Two tandem shafts for single-pass semi-slitting on lines less than 1” apart. Ideal for smaller width decals.

- Model Sizes: 18”, 24”, 30”, 36” & 42”

- Sheet Size Minimum: 4” x 4”

- Stocks: 1 mil. up to 40 pt.

- Electrical Requirement: 110 volts, 1 phase

DS Specifications

Double head slitting / semi-slitting / perforating / scoring machine capable of simultaneous applications.

- Model Sizes: 18”, 24”, 30”, 36” & 42”

- Sheet Size Minimum: 4” x 4”

- Stocks: 1 mil. up to 40 pt.

- Electrical Requirement: 110 volts, 1 phase

Allegra Marketing Print Mail, Norfolk, VA, installed an 18” Semi-Slitter model.

Allegra Marketing is a full-service marketing and print communications company. Allegra’s owner, Curtis Hoessly, visited the Rollem booth at Printing United 2022 to research what options Rollem offered for kiss-cutting pressure sensitive material. Following the demonstration and explanation of the functions of the machine, Allegra ordered and received the installation of an 18” wide Semi-Slitter model to apply both face and back slits to most of the shop’s PSA stocks. “The addition of our Semi-Slitting machine greatly improved our liner stock partial slitting for both face and back slits,” states Curtis Hoessly.

Dixie Signs & Decals, Inc., Florence, AL, upgrades kiss-cutting technology with a Rollem 36” Semi-Slitter model.

Dixie Signs & Decals, Inc. has been a manufacturer of custom decals, nameplates, and pressure sensitive labels for over 37 years.

There are several areas that we seek to constantly improve.

Production equipment: By reinvesting gains into modern technology and automation we are achieving the goals of our focus, in short, that goal is to make it easy for our folks to produce excellent products which in turn makes happy, stress free customers. “Realizing our kiss-cutting methods were in need of updating, we met with Rollem at the Printing United trade show to see a demonstration on their Semi-Slitter model. We were very impressed with the speed and depth of cut accuracy this model offers. The 36” width was ideal to handle our largest products requiring back slitting. Since the day it was installed, we’re very pleased with the ease of operation and dependability of our Rollem Semi-Slitter”, states Richard Milberger, President.

Marian Mexico, El Paso, TX installed a 24" Semi-Slitter model.

Marian Mexico of El Paso, TX was established in 1954 and is a global manufacturer of precision die-cut components made of innovative flexible materials.

They have 11 locations serving companies all over the world. Marian installed Rollem’s Semi-Slitter to aid in production of their component manufacturing to meets the company’s high quality standards.

The Semi-Slitter is the top choice of sign and label companies to kiss-cut labels and stickers. Rollem’s advanced SS Semi-Slitting/ Kiss-cutting slitters allow you to back or face-slit stocks with precisely controlled cuts and easy depth adjustments on all types of pressure sensitive adhesives (PSA).

The following companies utilize Semi-Slitting systems to improve the accuracy of their PSA slitting processes while also increasing production turn-around times:

Identity Group, Brunswick, ME installed a 24” Semi-Slitter

Traffic Safety Supply Company, Portland, OR installed a 30” model

Decalcorama Inc. of Quebec Canada installed a 36” model

Allied Graphics of St. Michael, NM installed a 42” model.